Raw materials

Functional Minerals for Industrial Performance

Selected Products from Our Portfolio

Micaceous Iron Oxide (MIO), Wollastonite, Phlogopite & Muscovite Mica, Talc, and Kaolin Clay are just a few examples of the functional raw materials we have successfully sourced and supplied to our customers worldwide.

Micaceous Iron Oxide (MIO)

Micaceous Iron Oxide (MIO)

Micaceous Iron Oxide (MIO)

Micaceous Iron Oxide (MIO)

Micaceous Iron Oxide (MIO)

Unsichtbar

Characteristics & Advantages

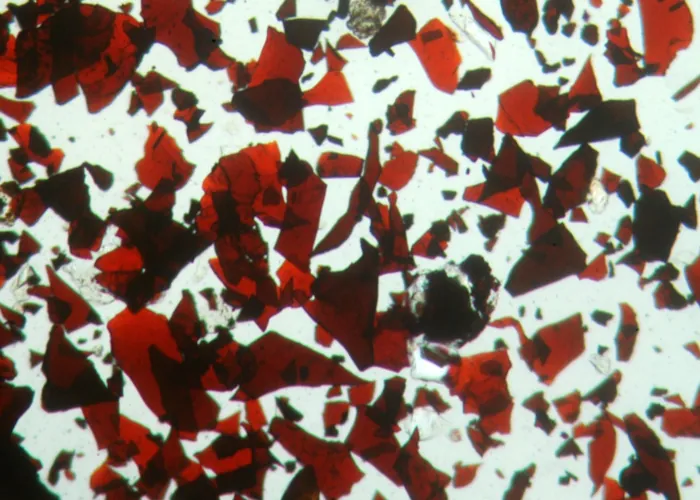

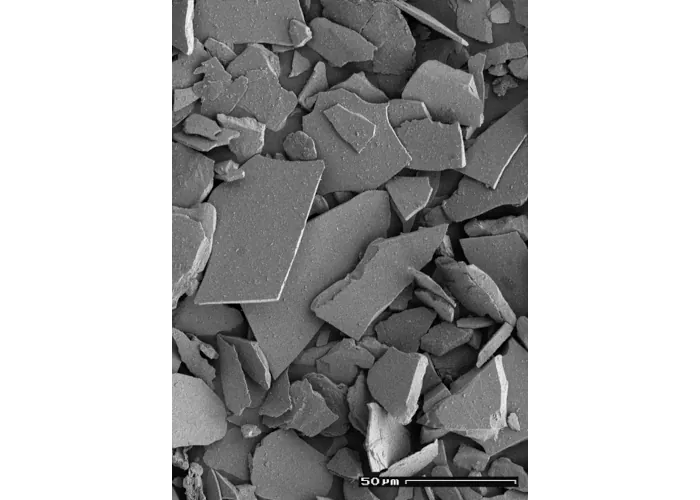

MIO (Specularite) is a lamellar form of Hematite (Iron-III-Oxide). The occurrence of this platy form is quite rare.

TaGed is in the position to supply high lamellar MIO (EN ISO 10601 – Grade A) for all industries such as coatings, ceramics, or friction industry, both as raw material (MIOTAG HL) or final product (MIOTAG SG).

TaGed is in the position to supply high lamellar MIO (EN ISO 10601 – Grade A) for all industries such as coatings, ceramics, or friction industry, both as raw material (MIOTAG HL) or final product (MIOTAG SG).

MIO’s unique properties, such as UV-ray absorption to protect polymer binders from degradation or barrier effects against environmental exposition, make it an indispensable ingredient in high-quality anti-corrosion paints.

MIO can also be used as an ingredient in friction material formulations, such as brake pads or linings, due to its high-temperature stability and acceptable hardness.

Compared to commonly used granular iron oxide, MIO offers a significantly improved coefficient of friction due to its lamellar structure, resulting in enhanced performance.

Mica (Phlogopite & Muscovite) & Wollastonite

Muscovite

Phlogopite

Wollastonite

Characteristics

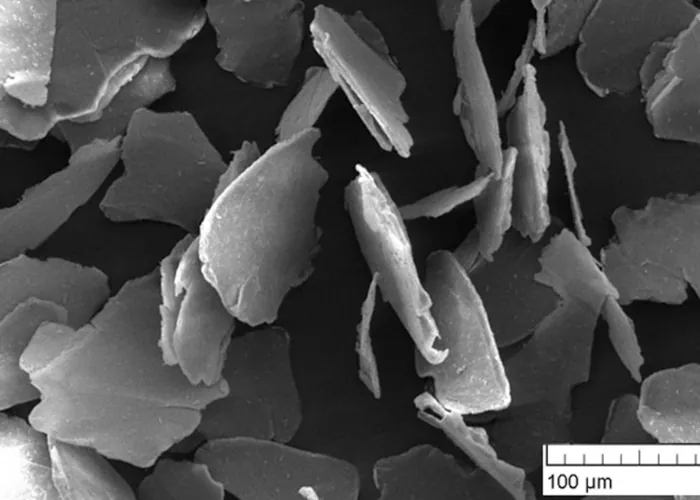

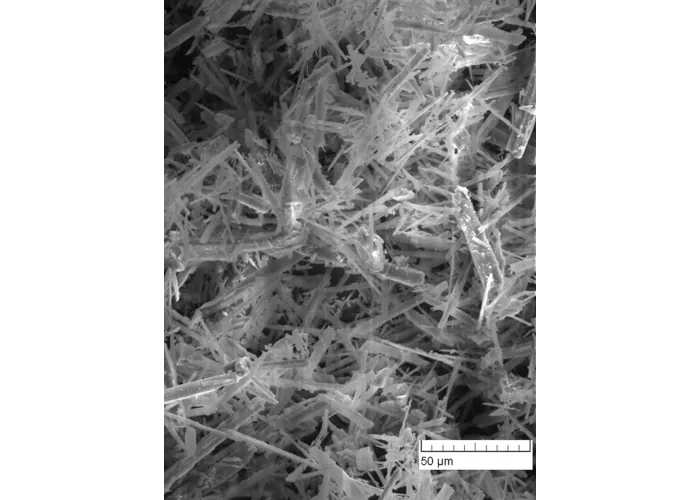

High-aspect-ratio functional minerals, such as phlogopite, muscovite, and wollastonite, play a significant role in enhancing thermoplastic applications due to their unique structural and compositional properties. These minerals, characterized by their platy or acicular structures, are particularly beneficial based on their geometric feature as it allows the mineral particles to create a robust network within the polymer matrix, leading to improved mechanical properties and performance of the thermoplastics.

Mechanical Enhancement

The incorporation of these high-aspect-ratio minerals significantly enhances the mechanical strength and stiffness of thermoplastics.

For example, phlogopite and muscovite, both types of mica, are renowned for their exceptional mechanical properties and high elasticity.

When these minerals are incorporated into thermoplastics, they provide enhanced tensile and flexural strength, which are essential for applications requiring high durability and load-bearing capacity.

Wollastonite, with its acicular structure, also contributes to the improved toughness and impact resistance of the polymer composites. This enhancement is particularly valuable in automotive and construction industries where mechanical performance is critical.

For example, phlogopite and muscovite, both types of mica, are renowned for their exceptional mechanical properties and high elasticity.

When these minerals are incorporated into thermoplastics, they provide enhanced tensile and flexural strength, which are essential for applications requiring high durability and load-bearing capacity.

Wollastonite, with its acicular structure, also contributes to the improved toughness and impact resistance of the polymer composites. This enhancement is particularly valuable in automotive and construction industries where mechanical performance is critical.

Thermal Benefits

These minerals confer remarkable thermal stability and improved heat resistance to thermoplastic materials.

Their inherent thermal properties reduce the thermal expansion of the composite, ensuring that the thermoplastics maintain their dimensional integrity under varying temperatures.

Moreover, muscovite and phlogopite provide excellent insulation and fire-retardant properties due to their high degradation temperatures and low thermal conductivity.

This makes them ideal for applications in electronics and appliances where thermal management is essential.

Wollastonite also enhances the heat distortion temperature of thermoplastics, allowing them to perform efficiently in high-temperature environments.

Their inherent thermal properties reduce the thermal expansion of the composite, ensuring that the thermoplastics maintain their dimensional integrity under varying temperatures.

Moreover, muscovite and phlogopite provide excellent insulation and fire-retardant properties due to their high degradation temperatures and low thermal conductivity.

This makes them ideal for applications in electronics and appliances where thermal management is essential.

Wollastonite also enhances the heat distortion temperature of thermoplastics, allowing them to perform efficiently in high-temperature environments.

Processing Advantages

In addition to the mechanical and thermal benefits, the use of high-aspect-ratio minerals can enhance the processing of thermoplastics.

These minerals allow for better flow and distribution of the polymer during molding and extrusion processes.

This results in smoother surfaces and more consistent product quality.

Furthermore, the inclusion of these minerals can reduce the overall material costs, as their high efficiency allows for lower loadings without compromising the composite properties.

These minerals allow for better flow and distribution of the polymer during molding and extrusion processes.

This results in smoother surfaces and more consistent product quality.

Furthermore, the inclusion of these minerals can reduce the overall material costs, as their high efficiency allows for lower loadings without compromising the composite properties.

Applications

The enhanced properties offered by high-aspect-ratio functional minerals make them suitable for a wide range of applications.

For example, in the automotive industry, these minerals are used in interior and exterior components to improve durability and reduce weight.

In the field of electronics, their thermal stability and insulating properties ensure the performance and safety of components such as circuit housings.

Additionally, in construction, these enhancements extend the lifespan and enhance the resilience of materials used in building infrastructure.

For example, in the automotive industry, these minerals are used in interior and exterior components to improve durability and reduce weight.

In the field of electronics, their thermal stability and insulating properties ensure the performance and safety of components such as circuit housings.

Additionally, in construction, these enhancements extend the lifespan and enhance the resilience of materials used in building infrastructure.

Conclusion

The integration of phlogopite, muscovite, and wollastonite into thermoplastics provides a multifaceted improvement to the materials’ performance.

Their ability to enhance mechanical strength, thermal stability, and processing efficiency while potentially reducing material costs underscores their value across various industries, addressing both performance and economic demands.

Their ability to enhance mechanical strength, thermal stability, and processing efficiency while potentially reducing material costs underscores their value across various industries, addressing both performance and economic demands.

Call us now

Write an Email